Sugar residue resources in sugar food processing plants are very rich. Sugar dregs are pure biological fermentation residues and are leftovers of oligosaccharides, containing part of sugar and colloidal protein, non-toxic and harmless, with a pH of 6.5-6.8, and rich in organic matter (70-74%), protein and amino acids. A large amount of sugar residue produced in industrial production is a high-quality raw material for organic fertilizer. We can reuse these sugar residues through organic fertilizer production process and equipment.

Soil organic matter refers to various forms of carbonaceous organic compounds in soil. It refers to the substance derived from the life in the soil. It is a substance in the soil, not a soil mineral. It is the most active part of the soil, the basis of soil fertility, and one of the important indicators to measure soil fertility. Organic fertilizer can improve the soil

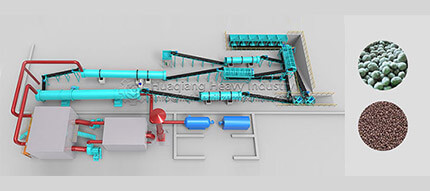

The application of small-scale organic fertilizer production technology is very flexible, which can meet the needs of families, small farms and pastures. How to produce fertilizer, the configuration of 5000 tons of organic fertilizer equipment includes: trough fermentation compost turner, forklift feeder, drum screening machine, pulverizer, horizontal mixer, organic fertilizer granulation machine, dryer, cooler, packaging machine, etc.

As an organic fertilizer machine factory, we strive to develop better in the future, promote new production technologies, share new discoveries and breakthroughs in the market, and seek development. The overall promotion of the enterprise has changed our development direction and made our future more clear. Whether it is the quality of the equipment or the quality of the technology, the after-sales service is relatively good in the industry. We conscientiously manufacture new equipment, are responsible for our own products, and are responsible for the safe production of users. Starting from the details, we carefully create excellent products in the industry.