Basis and conditions for the establishment of small-scale organic fertilizer production line equipment

2024/10/18

With the rapid development of animal husbandry and planting in China, a large number of livestock manure produced by large-scale breeding can not be disposed in time and become a source of pollution. How to treat these pollution sources from the source and make rational use of them as soon as possible? Considering various factors, the ideal way is to recycle these wastes by using all kinds of large, medium and small organic fertilizer production lines and their processing equipment.

Basis and conditions for the establishment of small-scale organic fertilizer production line equipment

1. The quality of this product meets the national standards for organic fertilizer, special fertilizer for green food and organic compound fertilizer.

2. Product models are divided into five series: grain, vegetables (melons and fruits, vegetable leaves), fruit trees, flowers and lawns. In each series, several models are prepared according to the growth characteristics of crops.

3. The supply of raw materials is reliable. The main raw materials of this product are livestock manure, and the auxiliary materials include peat, sawdust, straw, bean cake, horn bone powder and other wastes. The supply of surrounding materials shall not be less than 70 tons / day;

4. The main raw materials of organic fertilizer production include: pig manure, cow manure, chicken manure, etc; Ingredients include: straw, straw, charcoal, straw carbon, rice husk, etc.

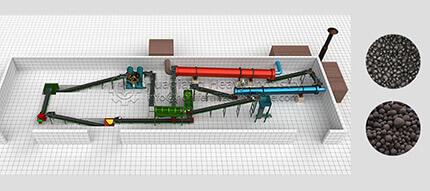

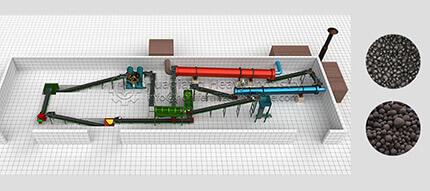

5. The production process of organic fertilizer basically includes: inoculation and fermentation of organic materials (pre fermentation), main fermentation, crushing, compounding and mixing, drying, granulation, cooling, screening, metering and packaging, etc.

Characteristics of production process of small organic fertilizer production line:

Anaerobic fermentation and high-temperature two-stage fermentation are used to recover and utilize bioenergy. The project plans to use biogas for power generation, using mature gas-fired generator units or special biogas generator units.

The organic fertilizer granulator can produce solid spherical particles at the moisture content of 20% ~ 40%, which greatly saves energy and equipment and improves the efficiency

In the drying process, it has the functions of polishing and mixing circles to make the particles more smooth.

It can be pure organic fertilizer granulation, or organic and inorganic fertilizer granulation, with no special requirements for granulation materials.