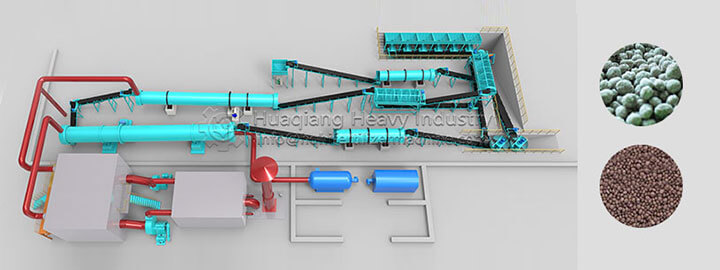

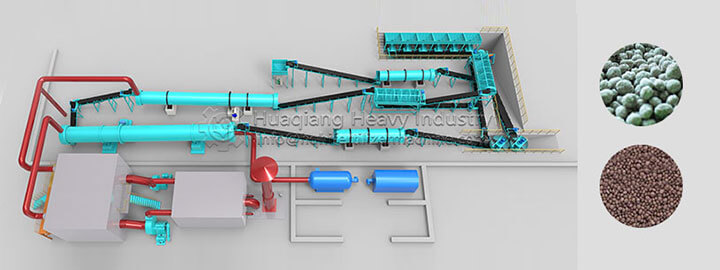

In a complete set of organic fertilizer manufacturing process, granulation is the key process in the whole production process. The productivity, particle strength and particle shape of fertilizer granulator directly affect the quality of products.

In many fertilizer equipment manufacturing enterprises, more NPK fertilizer granulators are drum granulator, roller extrusion granulator and disc granulator. NPK fertilizer granulator as a long-standing fertilizer equipment, has experienced a variety of materials, but any equipment has its advantages and disadvantages. With the diversification of raw materials, organic fertilizer equipment manufacturers continue to develop new granulation equipment.

In the production of common organic fertilizer, there is a new type of fertilizer granulator, which has high production efficiency and good product quality. In the organic-inorganic compound fertilizer, there is also a new type of compound fertilizer granulator, which is improved on the basis of the mixed granulator. The problems of material wall extrusion and particle generation are solved, and the particle appearance is also very beautiful.

The diversification of raw materials promotes the diversification of organic fertilizer granulation equipment, and equipment suitable for its own materials can be used to maximize the performance of the entire organic fertilizer equipment.