In the current situation of fierce market competition and rising raw material costs, how to reduce production costs has become the focus of fertilizer enterprises. By optimizing fertilizer production lines, upgrading equipment, and increasing automation, companies can effectively reduce energy consumption, reduce labor costs, and improve production efficiency, helping to reduce overall production costs by 30%.

1. Adopt efficient and energy-saving fertilizer granulator to reduce energy consumption

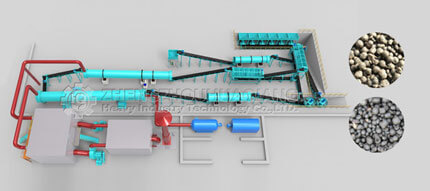

Granulation is a crucial link in npk production line and organic fertilizer production, choosing the right fertilizer granulation machine can not only improve the yield, but also reduce energy consumption. For example:

• Double roller press granulator: The use of dry granulation, no drying, significantly saving fuel and power costs.

• Disc granulator: low energy consumption, simple structure, low maintenance cost, suitable for small and medium-sized enterprises.

• Drum granulator: suitable for large-scale production, high degree of automation, improve production efficiency.

2. Introduce automation equipment to reduce labor costs

Automatic control system can optimize the batching, mixing, granulation, drying and other production links, reduce manual operation, improve production continuity. Intelligent fertilizer production lines can reduce labor needs by more than 30%, thereby reducing labor costs.

3. Optimize energy utilization and improve equipment efficiency

In the npk production line, the drying process consumes a lot of energy. Energy-saving equipment such as low temperature drying and high efficiency hot blast stove can reduce energy consumption. At the same time, reasonable allocation of crusher, mixer and other auxiliary equipment, reduce repeated processing, improve equipment utilization, reduce waste.

4. Improve the utilization rate of raw materials and reduce losses

Through fine management, improve the accuracy of raw material ratio and reduce raw material waste. In addition, equipped with screening equipment, the unqualified particles will be recycled and granulated, reduce waste, improve the yield.

Conclusion

By upgrading fertilizer production lines, optimizing the energy consumption control of fertilizer granulators, and improving the automation level of npk production lines, enterprises can effectively reduce production costs by 30%, improve market competitiveness, and achieve more sustainable development.