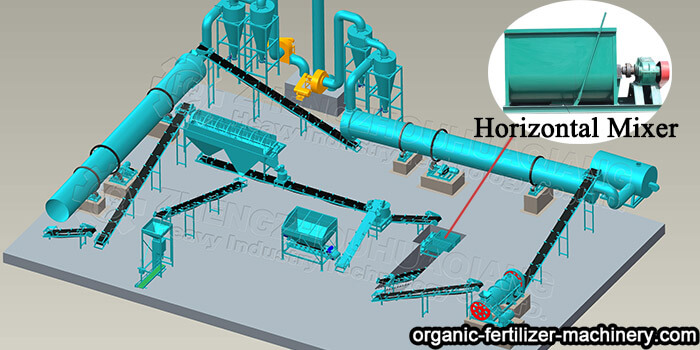

Single chemical fertilizer can no longer meet the needs of agriculture. Fertilizer products have gradually developed into multi-nutrient, targeted compound fertilizer granules. Organic fertilizer production line processes nutritious fertilizer products. Before fertilizer granulation, the horizontal mixer mixes all the raw materials to make the nutrients evenly distributed.

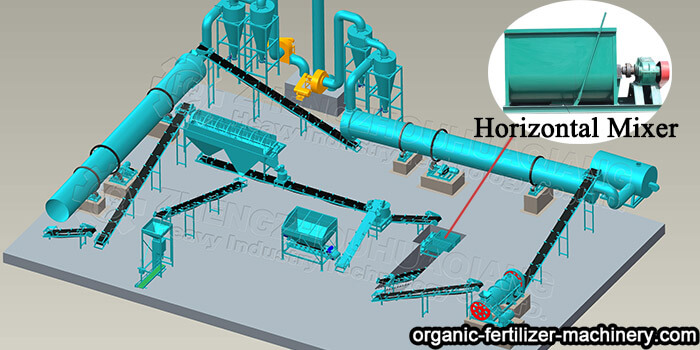

The horizontal mixer designed by our factory adopts a new design of stirring dragon, which can quickly complete uniform mixing, low energy consumption cutting, improve work efficiency and reduce power consumption.

When the organic fertilizer production line is running, the box of the horizontal mixer can not be filled, and the material should be controlled at about 60% - 70% of the volume of the box. After filling the material, mixing and stirring the material. When the spindle of the horizontal mixer rotates, the material moves forward in a spiral line under the action of the spiral blade of the mixer. The forward transportation of materials is accompanied by the rolling motion in the circumferential direction, forming the circular motion of front, back and forth, up and down. The coarse material with smaller bulk density can be fully contacted with the fine material with larger bulk density. The fine material can be adhered to the coarse material by using the bonding effect of water to achieve the uniformity of mixing. Because the material is driven by the agitation of the helical blade to form a transverse and radial circular movement, which realizes the flow of the mixture material in space, the material will not cake, ensuring the uniformity of the mixing of raw materials and facilitating the granulation of the organic fertilizer granulator.

Horizontal mixer simplifies the mixing treatment in organic fertilizer production. It can realize the large-scale, automated and specialized production of organic fertilizer production line. Horizontal mixer fully mixes organic fertilizer with inorganic fertilizer and other nutrients so that nutrients are evenly distributed on each organic fertilizer granule, which lays a foundation for the treatment of organic fertilizer granulator and improves the efficiency of organic fertilizer production.