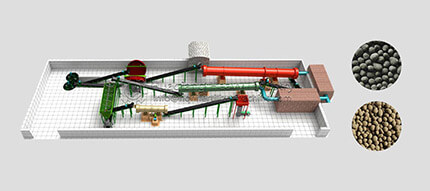

1. Ground turning machine or trough turning machine

The ground stacker does not need to build a trough, and directly puts the materials into a pile, using a 260 or 280 wheeled stacker to ride-through for stacking and fermentation.

Using trough fermentation, 6 fermentation tanks with a width of 6 meters and a length of 40-50 meters need to be built according to your production scale. The fermented material is continuously poured into the fermentation tank, and the turning and throwing machine is used for turning and throwing fermentation, which can achieve moisture regulation and stirring, uniform purpose, so that you can save a lot of labor. It can achieve the purpose of being fully decomposed.

2. Forklift

Use a shovel to move the fermented organic fertilizer to the semi-finished product stacking area, which is convenient for daily processing of the fermented organic fertilizer that is thrown by the dumper.

3. Screening machine

The fermented organic fertilizer is sieved, and the large pieces and sundries inside are separated to facilitate the next step of crushing and packaging.

4. Crusher

The large debris and stones in the sifted organic fertilizer are separated and crushed, which is beautiful and can ensure the quality of the product.

5. Blender

Mixing and mixing the sieved and crushed organic fertilizer can ensure the stability of the product quality, and at the same time play a mixing role when adding fertilizers and trace elements for the production of special fertilizers and various compound fertilizers.

6. Organic fertilizer granulator. Granulate the material. There are different kinds of fertilizer pellet machine in our factory.

7. Dryer, cooler. Dry and cool the finished particles.

8. Packaging machine

The organic fertilizer particles are granulated and directly packaged and sold.