What is the difference between powder and granular organic fertilizer production line equipment? When buying organic fertilizer equipment, you should know whether you are making powdered fertilizer or granular fertilizer. Their main difference is that one is organic fertilizer powder and the other is organic fertilizer granules. However, from the perspective of technology, the necessary equipment for making granules is more than powdered organic fertilizer equipment. The main purpose of making granular organic fertilizer is to facilitate bagging and transportation and prevent secondary fermentation of organic fertilizer, In terms of the degree of sale, granular organic fertilizers sell well. At the time of making organic fertilizers, powdered organic fertilizers are the preliminary process. Then, it is necessary to use the granulator in the organic fertilizer equipment to make granular organic fertilizers. Only with the organic fertilizer granulator can granular organic fertilizers be produced.

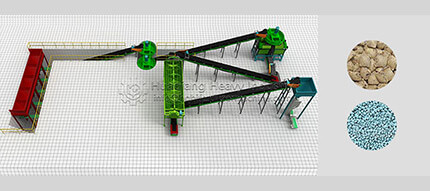

Organic fertilizer can be divided into powdery organic fertilizer and granular organic fertilizer according to the product status. The equipment and process for processing organic fertilizer are different between the two, resulting in inconsistent process equipment. The difference between processes is exactly the inclusion relationship. The granular organic fertilizer equipment process includes the powder organic fertilizer equipment processing process. As for the processing technology of granular organic fertilizer equipment as a complete organic fertilizer equipment, the process is composed of fermentation system, crushing system, screening system, batching system, mixing and stirring system, granulation system, drying system, cooling system, finished product screening system and packaging system. Except that the granulation process is unnecessary, other processes of the powdery fertilizer are similar.

Since the powdery fertilizer production line process in the organic fertilizer equipment is a part of the granular organic fertilizer production line process, it will be described in detail from the granular organic fertilizer equipment process. In this way, we can clear up the doubts of the customers who investigate the purchase. What kind of organic fertilizer equipment, process and equipment, necessary input and production line resources are selected by the customer, and the income is inconsistent. Therefore, when inspecting the process equipment of the production line, how to choose reasonable process equipment is the shortage of effective equipment resources. As the process part of the granular organic fertilizer equipment, the main process means of the powdery organic fertilizer equipment are as follows: the organic fertilizer materials such as livestock and poultry manure or domestic garbage, sludge, distiller's grains, biogas residue, etc. are fermented, decomposed, crushed, mixed and packaged to complete the processing of powdery organic fertilizer. Compared with the simple process of powdery fertilizer, granular organic fertilizer needs to be further processed. The basic process equipment of granular organic fertilizer equipment is fermentation, crushing, stirring, granulation, drying, cooling, coating and packaging. If there is no organic fertilizer dryer and organic fertilizer coating machine, it can be packaged, stored or sold after cooling after granulation.