Motor Power:1-20t/h

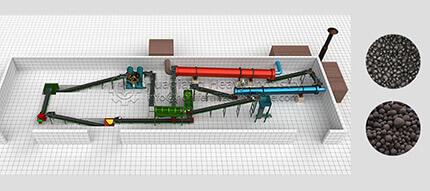

With livestock and poultry waste and agricultural waste as the main raw materials, organic fertilizer production line equipment not only created economic benefits for enterprises, but also made great contributions to human environmental engineering.

Motor Power:1-20t/h

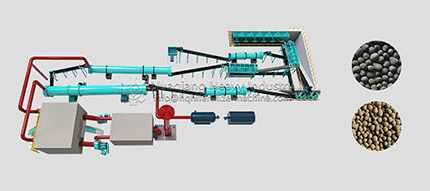

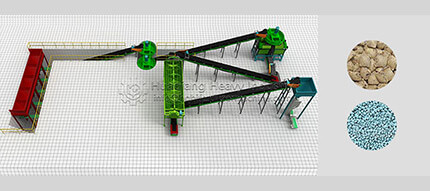

Compound fertilizer production process can be divided into: raw material ingredients, raw material mixing, raw material granulation, granule drying, granule cooling, granule grading, finished coating, final product packaging.

Motor Power:1-20t/h

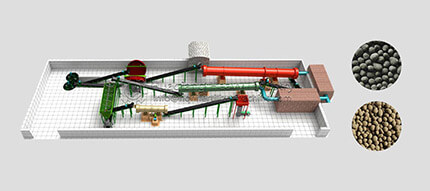

The bio-organic fertilizer production process is mainly the fermentation part and the production granulation part. Even if the raw materials for organic fertilizers are better fermented, granulation is also difficult. Therefore, when selecting equipment, you should be taken carefully.

Motor Power:1-20t/h

The disc granulation process has the advantages of short production process, simple structure, less investment and easy operation, and is suitable for small and medium-sized enterprises.

Motor Power:1-20t/h

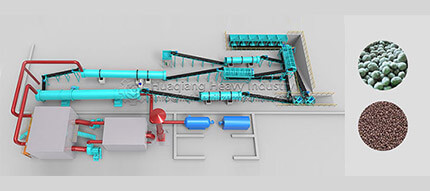

The new blended raw materials are fed into drum granulator at a uniform rate according to the balling rate. At the same time, the saturated steam is fed into the material layer as required, so that the granulation process can be granulated at a lower moisture content, which not only raises the temperature of the material, but also causes the material to be humidified, thereby reducing the drying load.

Motor Power:1-20t/h

Roller press pellets are widely used for the production of compound fertilizers. There are more than 20 kinds of materials that have been successfully applied to granulating.

Motor Power:1-20t/h

NPK bulking blending fertilizer production line is designed and manufactured according to the requirements of the compound fertilizer plant and fertilizer distributor. The productivity can reach to 10000 - 100000 tons.